With the DT Spare Parts brand, Diesel Technic stands for reliable branded spare parts with guaranteed quality – thanks to decades of experience in the automotive sector. Thanks to its own Diesel Technic Quality System (DTQS), the company ensures consistently high standards, certified in accordance with ISO 9001:2015 and supplemented by proven best practices.

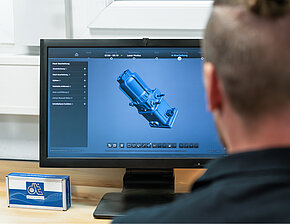

The central elements are continuous product optimisation (CIP) and the CAQ system (CAQ = Computer Aided Quality) as an interface between product management, technology and quality control. The DTQS comprises four consecutive processes along the quality supply chain: Product Development, Initial Sample Inspection, Series Inspection and Aftersales Support.

With the continuous development of the DTQS, Diesel Technic is setting new standards in the area of development and quality assurance. In recent years, a large number of forward-looking measures have been implemented – from digital process automation to the international expansion of technical capacities.

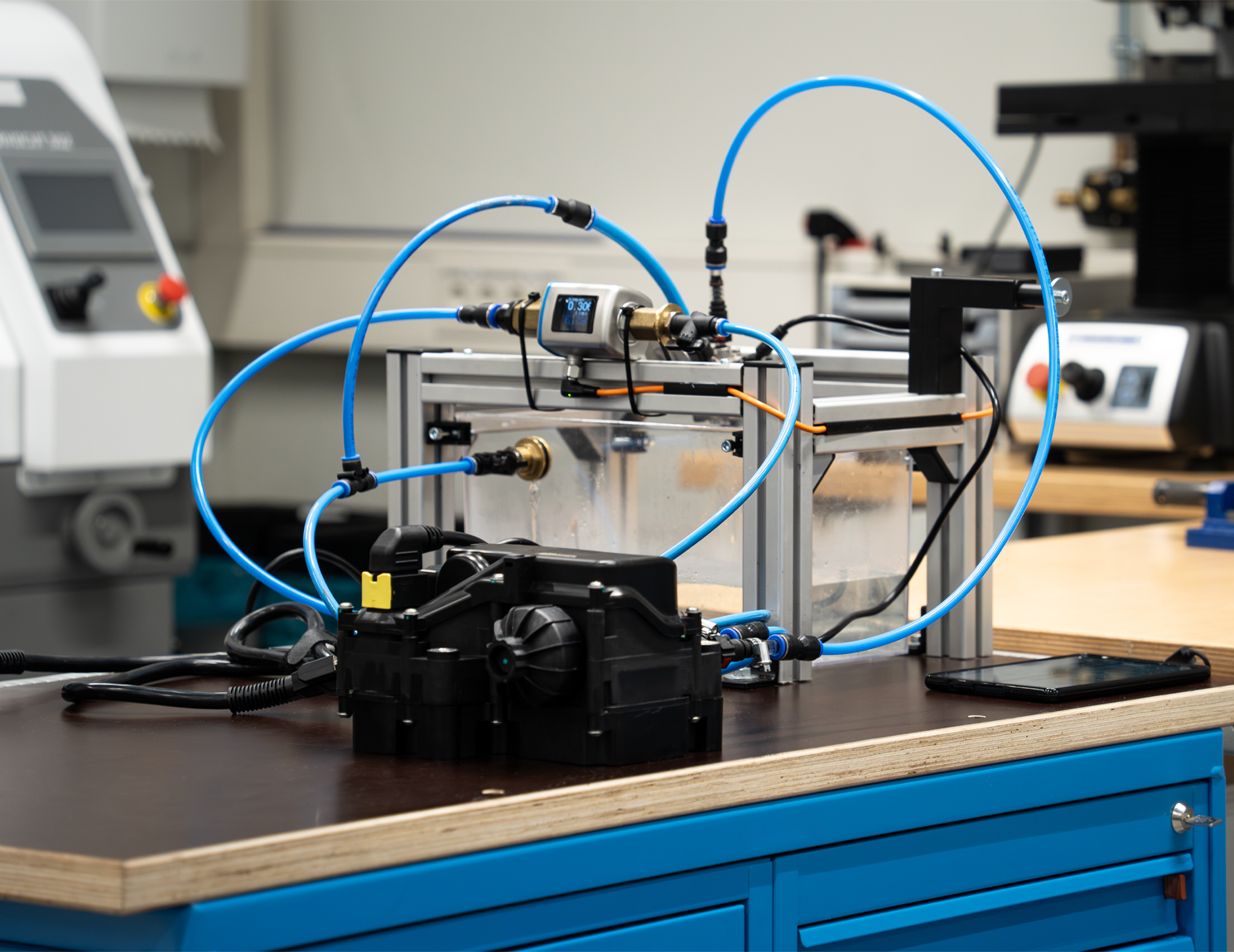

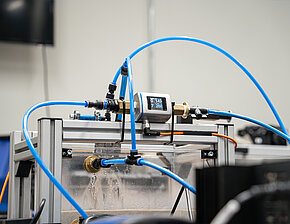

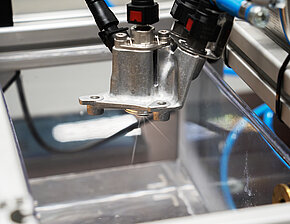

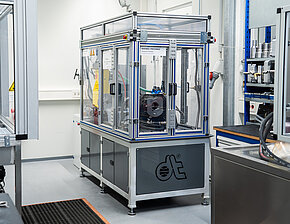

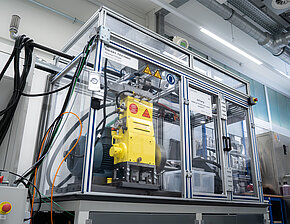

High-tech test systems for the highest demands

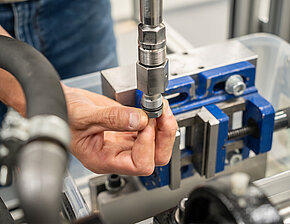

More than 35 multifunctional test benches are available at the main site in Kirchdorf, supplemented by various hardware and software developments. New additions include:

- A high-pressure hydraulic test bench with up to 3,500 bar for injection system components

- Special testing options for AdBlue systems

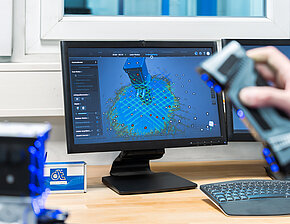

- A modern 3D hand-held scanner with associated software to expand our expertise in coordinate measuring technology

These developments ensure that Diesel Technic remains state-of-the-art in the future – both technologically and in terms of processes.

New technical field office in Dubai

With the opening of an engineering office in Dubai, Diesel Technic is emphasising the global aspirations of DTQS. In addition to technical supplier communication, the new branch office offers an independent test laboratory for a wide range of measurement and functional tests – another milestone in strengthening international quality assurance.

Systematic supplier management

Another focus is on the further development of technical supplier management. The centrepiece is the specially developed DTQS audit system – based on VDA 6.3 – supplemented by structured supplier evaluations, 8D reports in the event of deviations and comprehensive preventative measures to ensure product quality.

Structured competence – The DTQS at a glance

The Engineering & Development department at Diesel Technic is organised into various specialist areas. The development groups include the development and approval of digital design data, known as CAD data, and the associated drawings, as well as the sampling of new parts, including approval for series production. Technical supplier communication is also located here. In addition to carrying out testing and measuring tasks, the Test and Project group is also responsible for the development of innovative testing processes and patent management. The Quality Assurance department combines the creation of incoming goods inspection plans and operational quality assurance on the article. Aftersales Support deals with technical issues relating to Diesel Technic products and services.

With the DTQS, Diesel Technic is creating a strong combination of technological progress, global presence and quality awareness – for spare parts solutions that customers worldwide rely on.