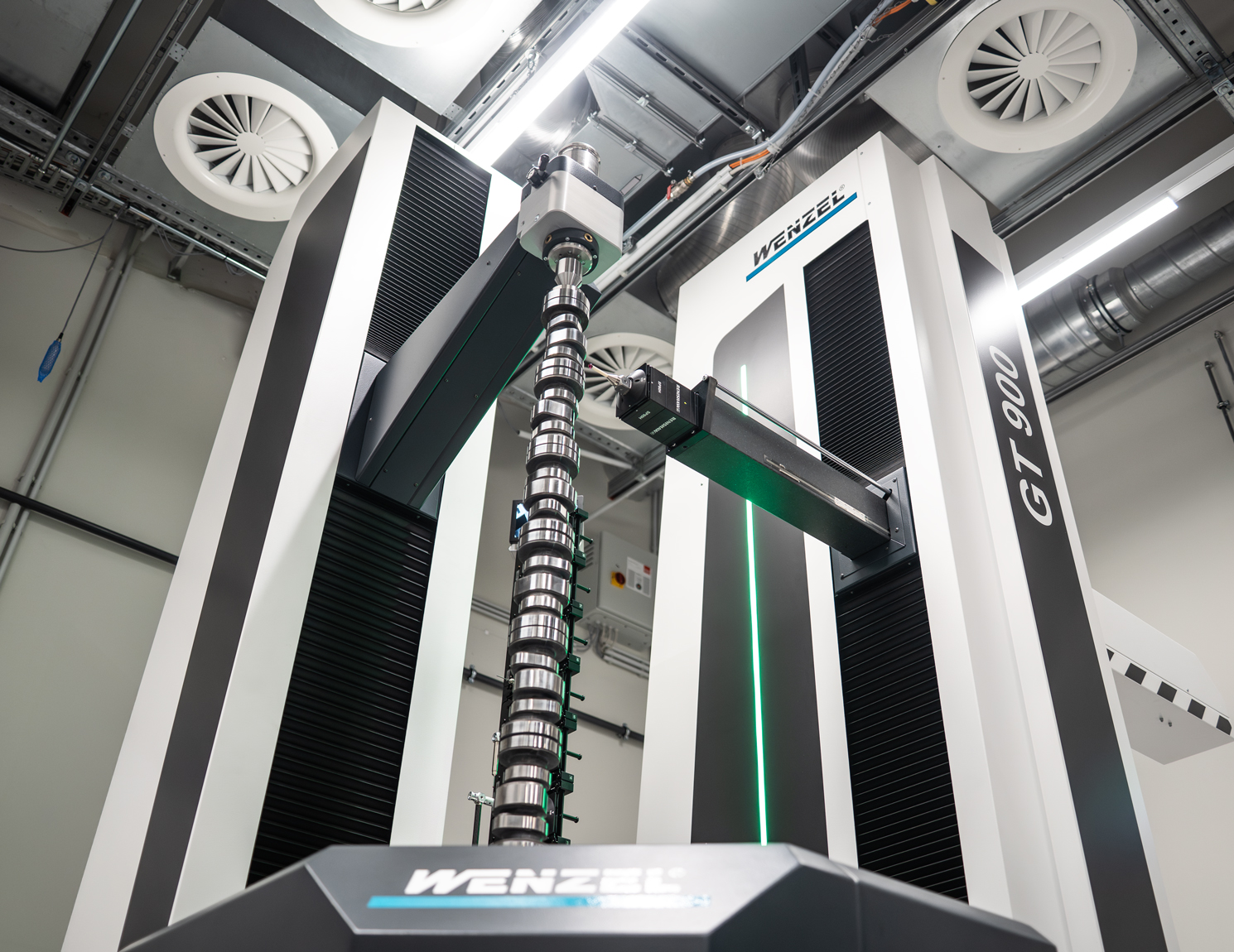

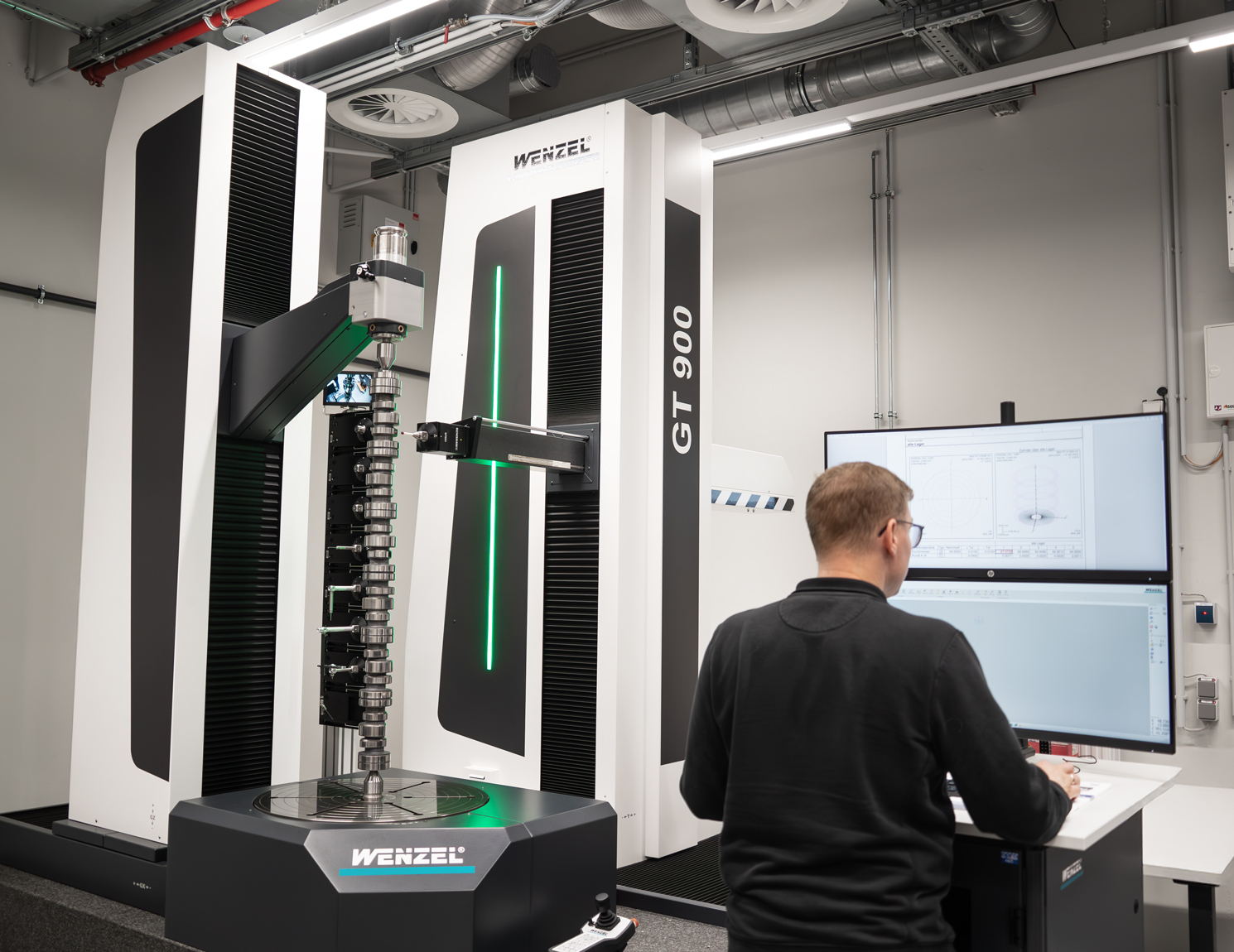

Diesel Technic is sending a clear signal for technological advancement and the highest quality standards: with its investment in the state-of-the-art Wenzel GT900 gear measuring machine, the company is specifically strengthening its technology and development division.

Powerful, precise and fully automatic: the advantages of the Wenzel GT900

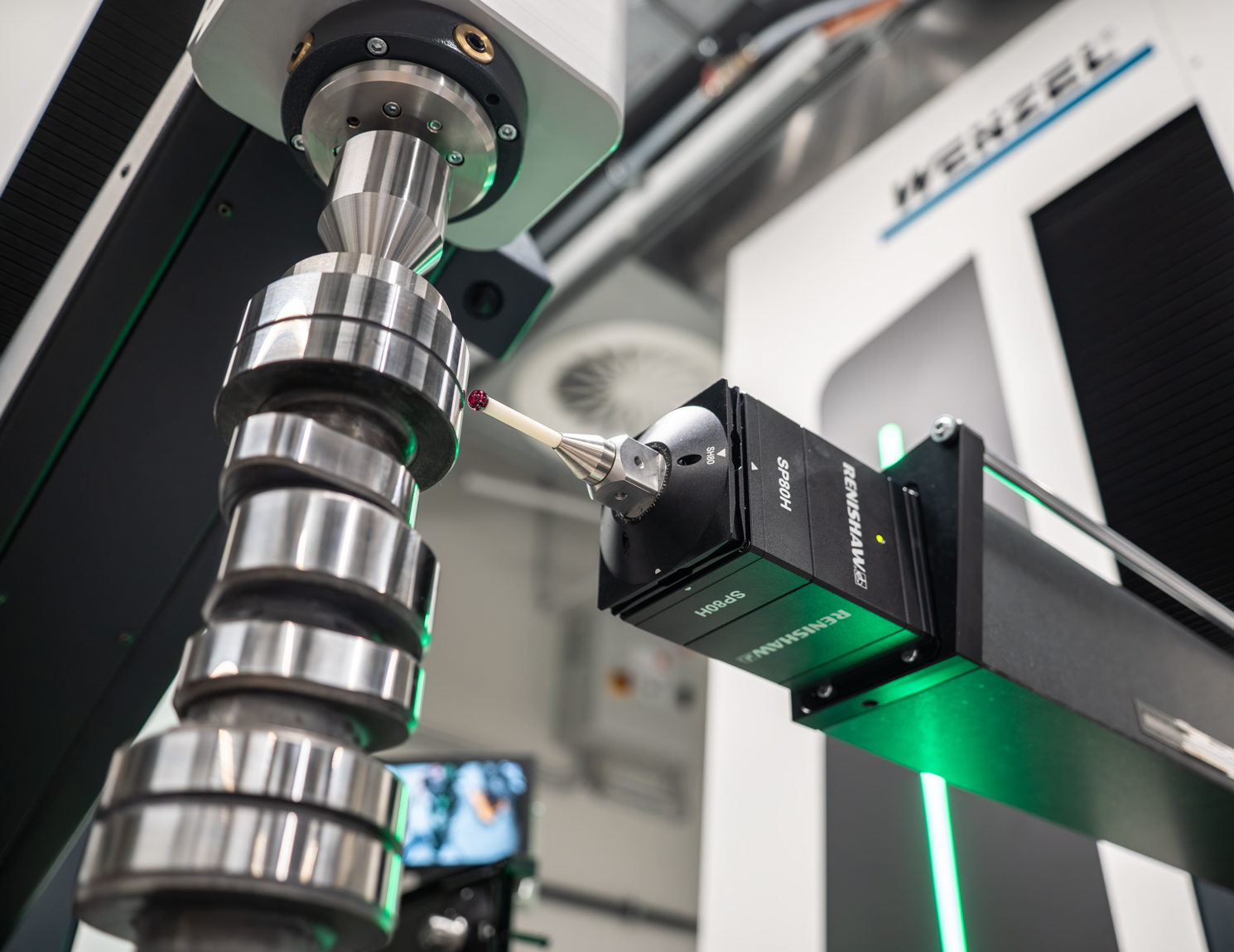

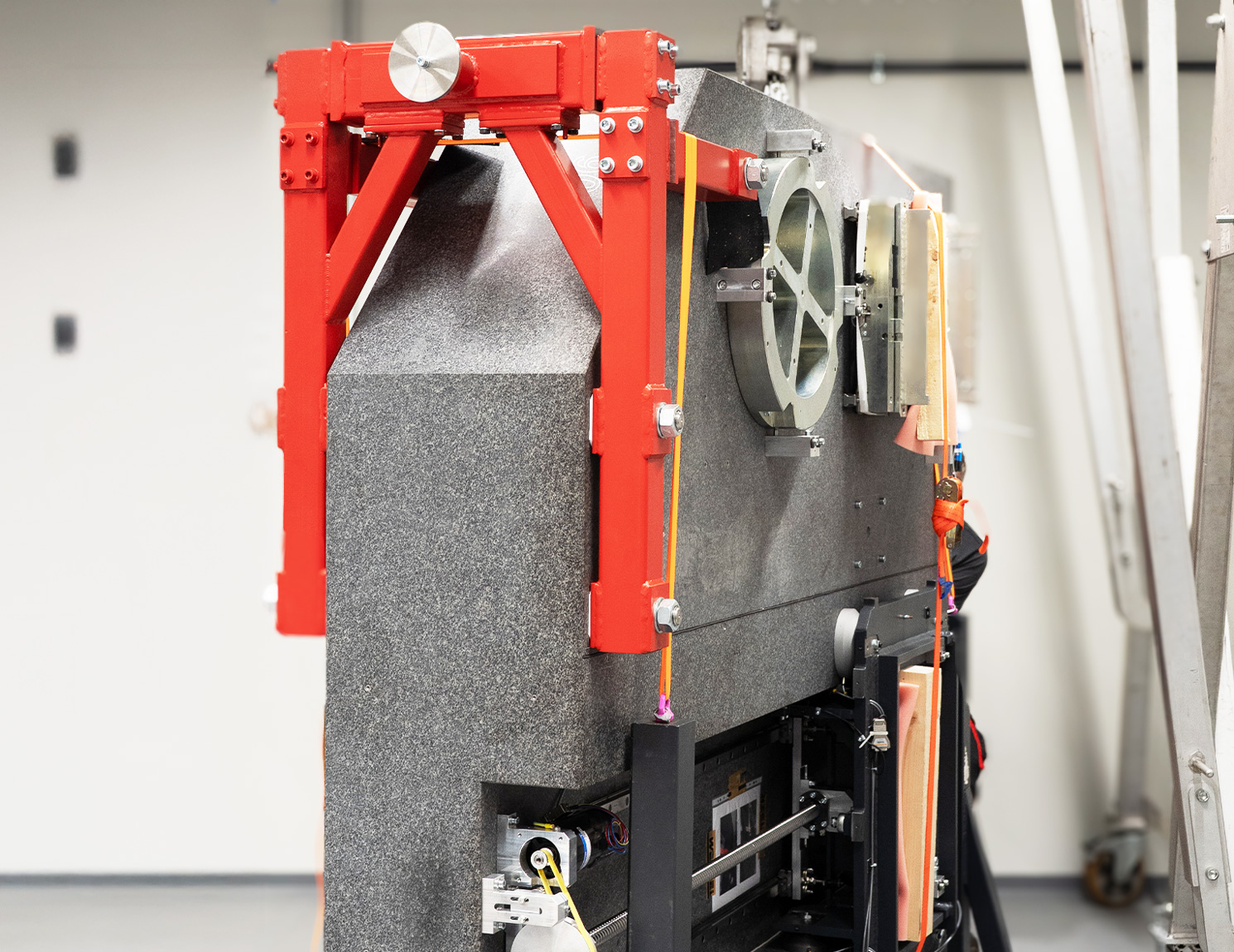

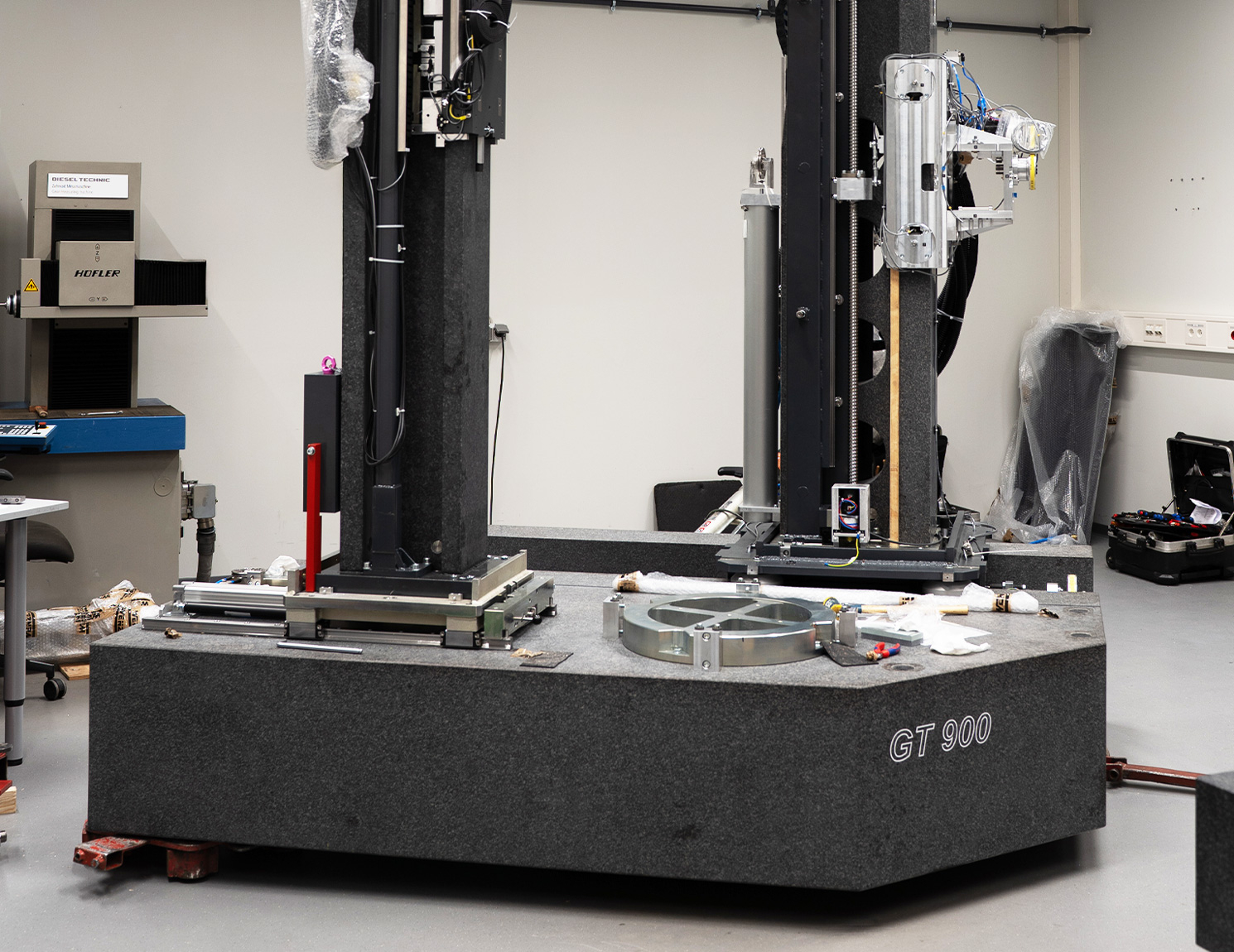

With the Wenzel GT900, Diesel Technic has acquired a high-precision measuring system of the latest generation, which impresses with a maximum item diameter of 900 mm, an item length of up to 1,500 mm, an item weight of up to 1,200 kg and a measuring accuracy of approximately 0.005 mm per metre.

The high degree of automation of the GT900 offers a massive reduction in configuration and measurement process times.

Direct CAD (computer-aided design) integration and intuitive evaluation of measurement results significantly accelerate product development and quality assurance processes. This allows even complex engine and transmission parts such as crankshafts, camshafts and other precision components to be measured and analysed efficiently.

Quality as a principle – DTQS as a foundation

The investment is another building block within the Diesel Technic Quality System (DTQS) – a company-wide quality system that is unique in the aftermarket and ensures high quality standards. With the Wenzel GT900, Diesel Technic has created the ideal conditions for further increasing precision in parts development and meeting the requirements of the international spare parts market.

Investing in the future – for the benefit of customers

With the highest investment ever made in a single measuring system, Diesel Technic is taking its technical infrastructure to a new level. The decision underlines the company's commitment to shortening time-to-market, expanding its product range in a targeted manner and sending a clear signal to its partners:

‘We are your reliable partner for high-precision spare parts – today and in the future.’